How Lenses Are Made at Our Lens Centre

Hakim Optical has invested millions of dollars in building four Canadian laboratories across the country. These labs utilize the latest German engineered and designed technology in software and hardware machinery to produce the ultimate quality lenses for our customers in a quick and efficient manner.

How Lenses are Produced

In some instances, your lenses can be made in-store at one of Hakim Optical’s One-Hour locations; however, if they need to be sent out, they’ll make their way to the closest full-scale lab. We have three locations in Ontario that include Etobicoke, Scarborough, and Richmond Hill as well as a lab in Winnipeg, Manitoba. Once the lab has received your order online from the store computer, a technician starts by choosing the correct lens blank (plastic or glass semi-finished lens) and size to custom make your prescription lenses with all the features and upgrades. There is also the possibility to choose finished single-vision lenses that are ready to be cut into the precise shape to fit your frame of choice.

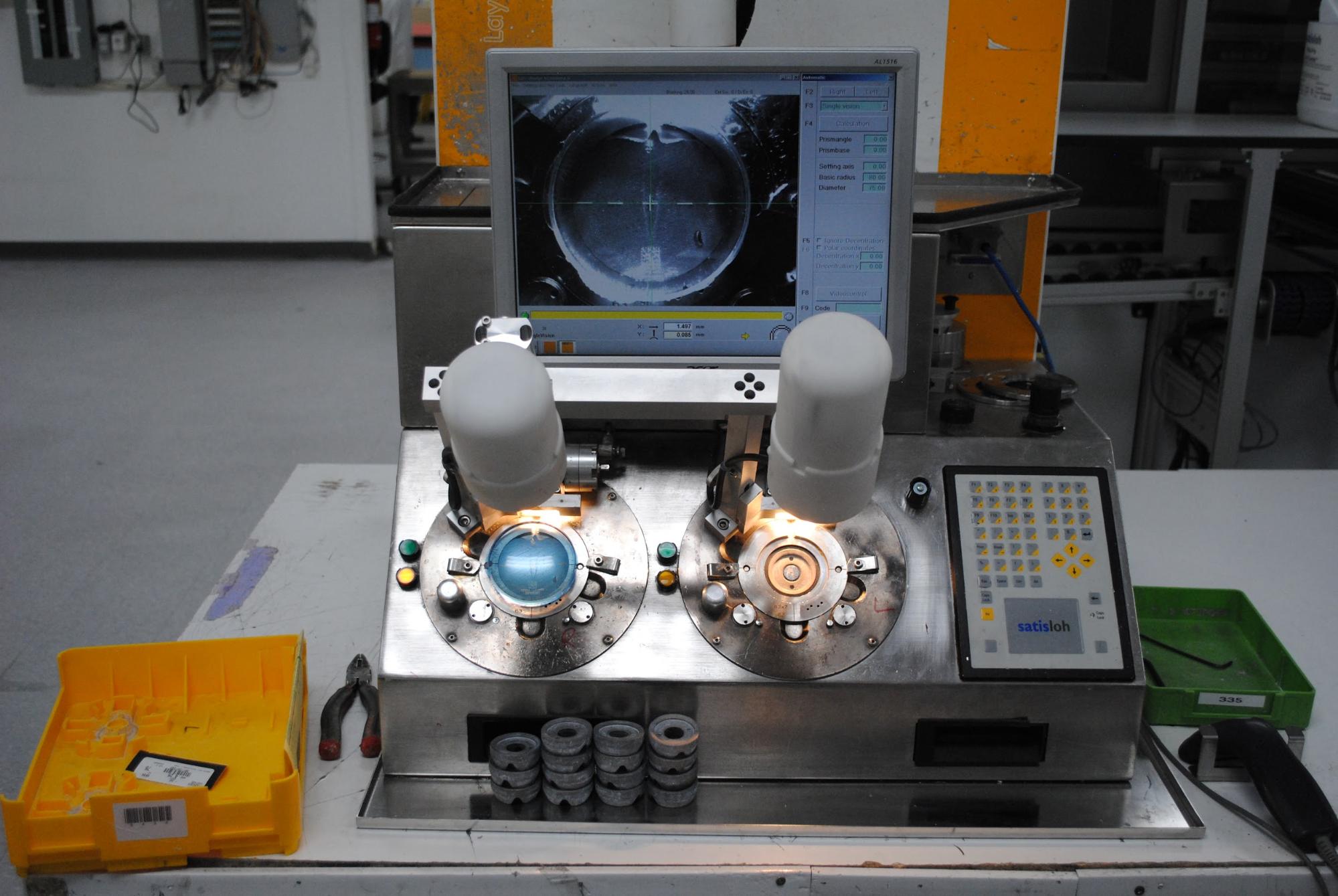

Semi-finished lenses are forwarded to the blocking department where they receive a blue protective film on the front surface. They are also blocked to a chuck holder using an alloy, pictured left.

Depending on the lenses, sometimes wax blocking is used as pictured here. The blocking, either alloy or wax, holds the lens in place during grinding and other processing steps.

During the next step, the lenses are placed into a specific tray on an active conveyor belt. Each tray contains a barcode that is read by a reader, as seen in the picture to the left, guiding it to the appropriate machine.

Pictured here is the German-engineered optical generator and will precisely grind the back (concave) surface of the lens with a computer calculated curvature to produce prescription lenses within a micron (1/1000 millimetre) precision.

The automated robotic equipment will place the barcoded tray back on the conveyor belt, and forward it to the next station. Polishing machines will polish each lens backside concave surface to the precision that produces the most accurate optical surface possible with today’s available technology.

The next step requires plastic lenses to receive one of two types of surface scratch-resistant coating; either standard scratch-resistant spin-coat or premium scratch-resistant dip-coat.

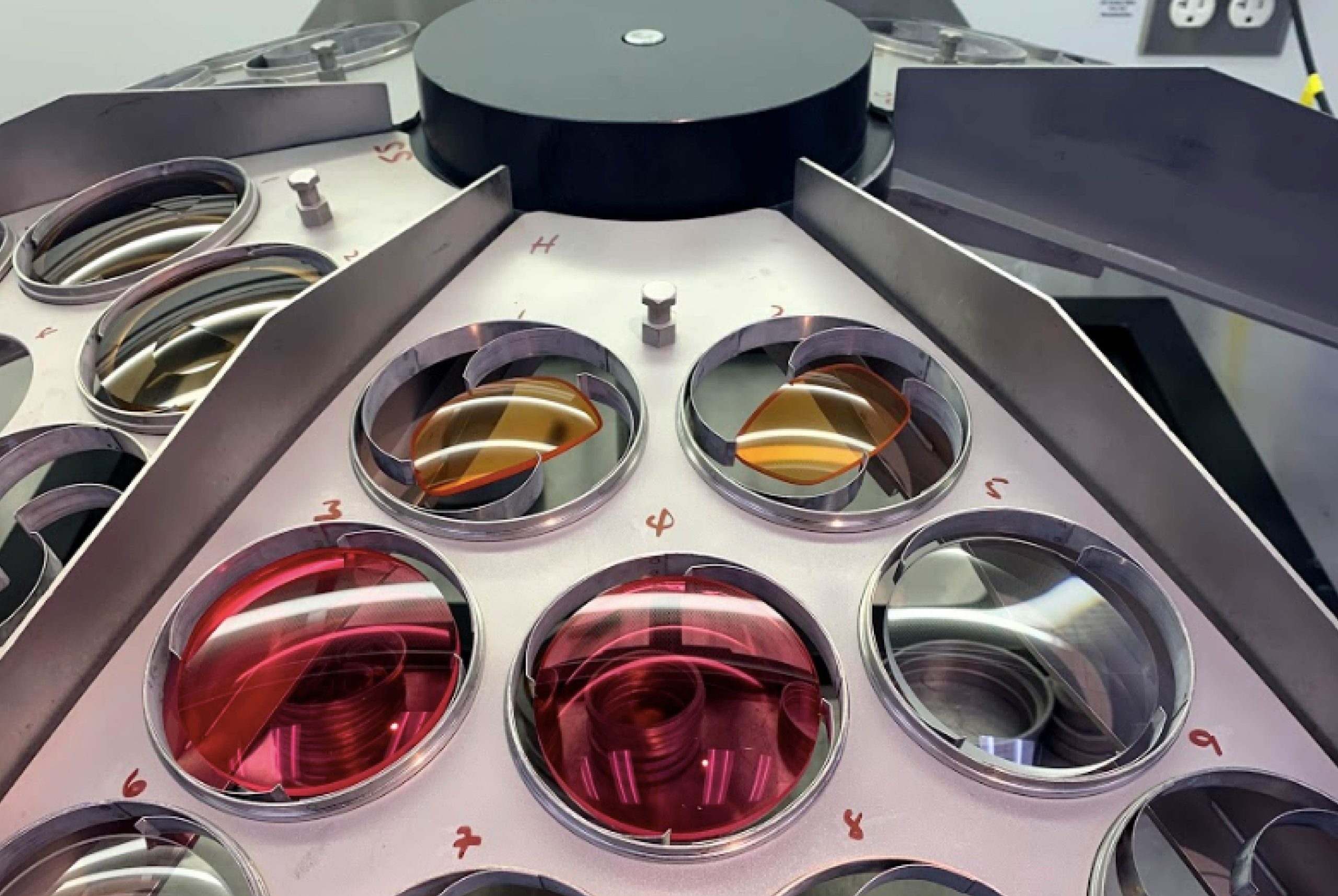

The lenses are inspected for surface quality and then forwarded to receive one of five different multi-layered anti-reflection coatings that are listed on the work-order. These coatings are applied using the German-engineered, high-precision in high vacuum deposition chambers pictured on the left.

At this stage, the finished lenses meeting all quality control requirements are forwarded to the finishing station.

At the finishing station, pictured left, the lenses are now ground-down into the precise shape, size, and bevel required to fit into the desired frame. Using the latest German-engineered finishing machine, a technician loads the lens and then confirms the frame shape before grinding the sides of the lens.

At the final production, a technician station assembles the lenses and frames to produce a finished pair of eyeglasses.

More time and manpower are required to assemble the semi-rimless frames with lenses. Full rimless frames require a highly skilled technician and cannot be automated.

The quality control station is the final check prior to shipping that requires the highest skilled technicians who scrutinize every pair of eyeglasses to meet and exceed the required guidelines set by the College of Opticians of the province. At this stage, eyeglasses that successfully pass are shipped to the store for pickup. Any eyeglasses that fail to pass are returned back for expedited processing.

At Hakim Optical, we have been serving our customers proudly since 1967. While our lens equipment has been upgraded over the last 50 years, our dedication to customer satisfaction and high-quality lenses has never wavered.

Stop into your nearest Hakim Optical location for more information or to pick out your next pair of glasses.

At Hakim Optical, we are committed to providing our customers with fast and simple solutions to their eyewear needs. Our expert staff, one-hour labs and low prices combine for the complete shopping experience.

Connect with us on Facebook, Twitter and Instagram for eye health tips and to always stay up-to-date on our latest promotions.